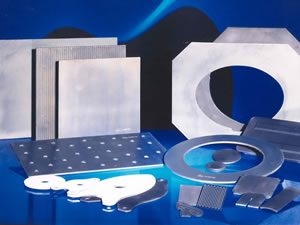

SiC kiln furniture

Beams, profiles and posts

SiC kiln furniture can create a more efficient use of the available kiln space and a saving in energy due to a reduction in the thermal mass.

- No porosity, therefore excellent oxidation and corrosion resistance

- Very good thermal shock resistance

- High modulus of rupture

- Stability of shape up to the maximum operating temperature (excellent long term creep-resistance)

- Low mass

- High degree of reliability and economy in service

- High surface quality

- Clean inner surfaces (no residue from the silicon zing process)

Batts, plate-setters and lavi-setter

SiC kiln furniture has excellent stability of shape and is a material of choice for fast firing applications (e.g. tableware production). It’s proven reliability in service owes much to its high thermal conductivity and high strength.

- Excellent oxidation and corrosion resistance

- Very good thermal shock resistance (which enables shorter firing cycles)

- High modules of rupture

- Stability of shape up to the maximum operating temperature (excellent long-term creep resistance)

- More efficient use of available kiln space due to enhanced setting density

- No contamination of ware being fired

- Low mass car superstructures

- High degree of reliability and economy in service

- No porosity, therefore excellent oxidation and corrosion resistance

- Very good thermal shock resistance

- Low mass

- High degree of reliability and economy in service

- Kiln car superstructures

Applications

Standard materials

Cordierite, alumina, nsic (nitride bond), rbsic (reaction bond)

See materials menu above for detail