Ceramic Batts

Ceramic batts are refractory tiles or slabs which are typically used as part of the kiln car superstructure and which also may support ware during the kiln firing cycle.

We have a wide range of batts available including:

- Plain

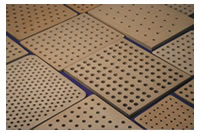

- Perforated Multi-hole

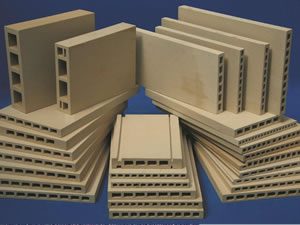

- Extruded / hollow

- Pressed

- Ribbed / grooved

- Featured batts, including recesses for location and mug placing

We offer: pressed ceramic batts

1000mm x 1000mm; Extruded Batts up to 1800mm x 840mm; Circular Discs up to 1092mm dia. Pressed Batts: These include plain which can be square, rectangular, shaped, circular or semi-circular, and be supplied in a varying range of size and thickness. Ribbed and grooved ceramic batts also tend to be pressed products.

1000mm x 1000mm; Extruded Batts up to 1800mm x 840mm; Circular Discs up to 1092mm dia. Pressed Batts: These include plain which can be square, rectangular, shaped, circular or semi-circular, and be supplied in a varying range of size and thickness. Ribbed and grooved ceramic batts also tend to be pressed products.

- Extruded batts strong yet lightweight

- Perforated batts to help heat flow

- Can be machined for small run orders

Applications

Standard materials

Cordierite, alumina, NSiC (nitride bond), RBSiC (reaction bond)

See Materials menu above for detail

Perforated batts

A whole host of configurations are available in this range, with some batts having as few as 21 holes and others ranging right up to 186 holes. Hole diameters in the standard products range from 6mm to 32mm.

Extruded batts

We offer a wide range of sizes with batt thinnesses of 18mm, 25mm and38mm. Extruded batts have a part-hollow section which means that less energy is needed to heat each batt when compared to solid batts. They can also be perforated to allow extra heat flow.