Adapting to Challenges: A Case Study in Custom Quality Control Solutions

In manufacturing, challenges are inevitable. However, the ability to quickly adapt and turn these challenges into opportunities for innovation is what sets successful businesses apart. A recent case with our team highlights how we responded to a customer’s specific needs by adjusting our quality control processes, ensuring the product met their complex requirements.

The Challenge: A Critical Feature with Strict Measurements

We were tasked with manufacturing a highly complex part with a critical feature. This feature was essential to the product’s functionality, and any deviation from the precise measurements would render the entire part unusable. The difficulty arose from the stringent measurement requirements for this feature, compounded by its location in a difficult-to-reach area of the part, making traditional measurement methods unfeasible.

The Solution: Custom Pass/Fail Gauge Design

Recognising the urgency and complexity of the task, we focused on a solution that would allow us to measure this critical feature with accuracy and efficiency. The result was a custom-designed pass/fail gauge, developed to meet the client’s exact specifications.

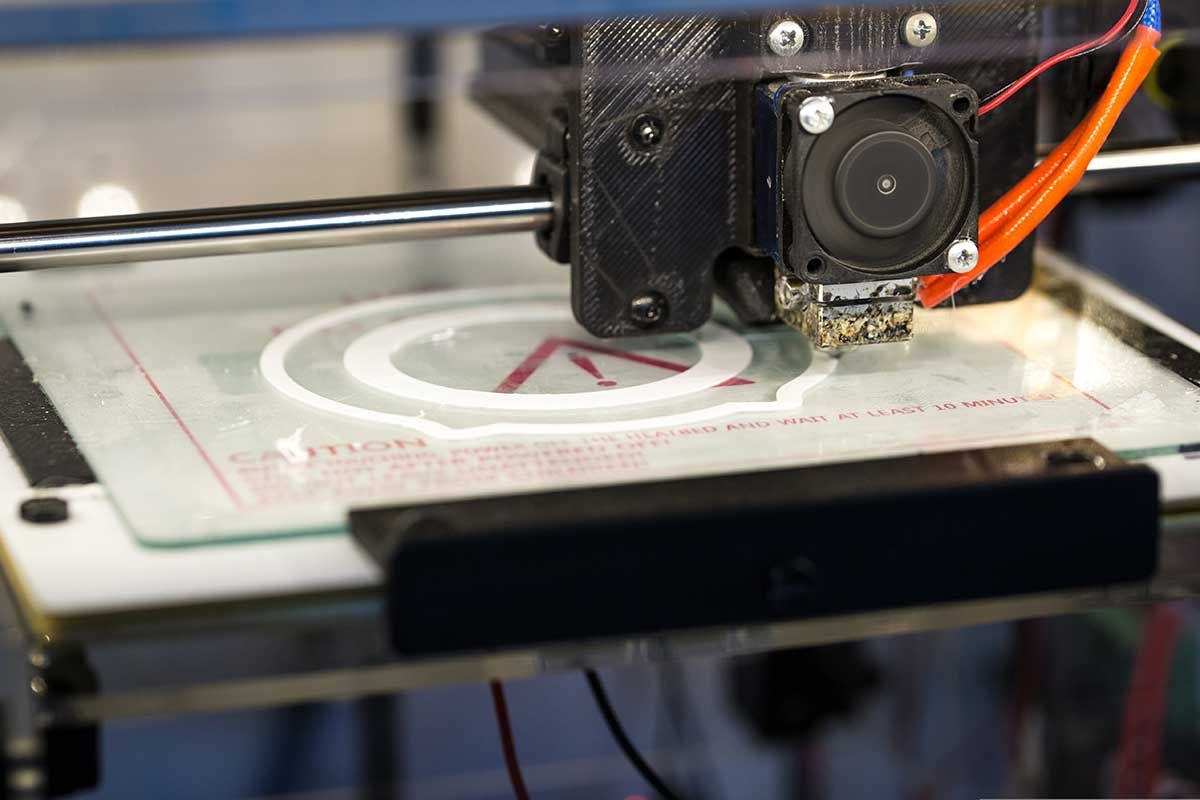

What set this solution apart was our ability to design and produce the gauge in just three days. By leveraging 3D printing technology, we created a durable plastic gauge that could withstand repeated inspections. This allowed us to conduct a yes/no inspection on every part, ensuring compliance with the customer’s stringent quality standards.

The Outcome: Swift and Accurate Quality Control

The introduction of this custom pass/fail gauge significantly improved our quality control process. It reduced inspection time while enhancing both accuracy and reliability. This proactive solution ensured a smooth production process, avoiding delays and delivering the product to the customer on time.

Why It Matters: Adaptability in Action

This client solution underscores the importance of adaptability in manufacturing. Instead of facing delays or compromising on quality, we identified an opportunity to innovate and solve the problem efficiently. By utilising 3D printing technology, we maintained the highest standards without impacting the project timeline. This flexibility highlights our ability to quickly respond to complex challenges and deliver tailored solutions that meet client expectations.

Conclusion: Turning Challenges into Opportunities

This experience demonstrates that challenges need not be obstacles but can be opportunities to drive innovation and improve processes. By adapting our quality control processes to meet the customer’s specific needs, we delivered a solution that not only met but exceeded their expectations.

Ultimately, our ability to adapt quickly and innovate ensures that we continue to meet the evolving demands of our clients and remain a trusted partner in delivering reliable solutions.